CHEAP VEHICLE WRAPS: The results.

Vehicle wrapping is one of those art forms where you really do want professionals working on your car. what we have here is the result of a cheap and low quality wrap. These are the most vivid representations of why it is important to see people like our highly trained staff at PROvinyl.

The bonnet.

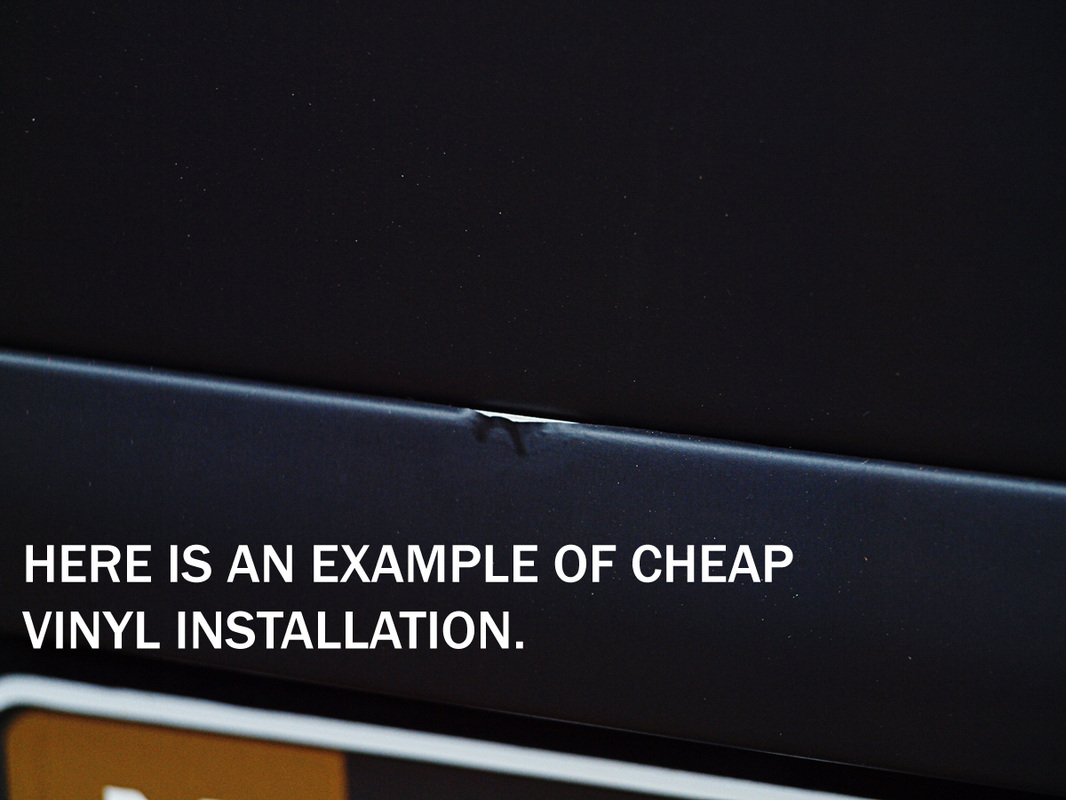

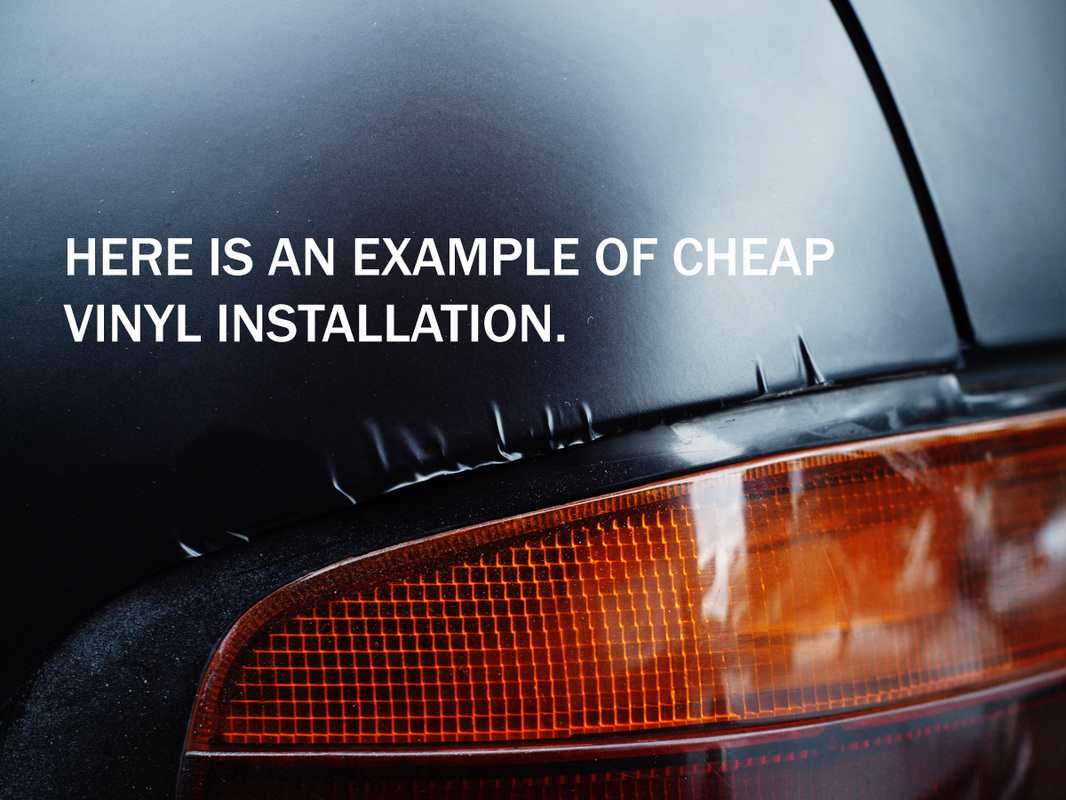

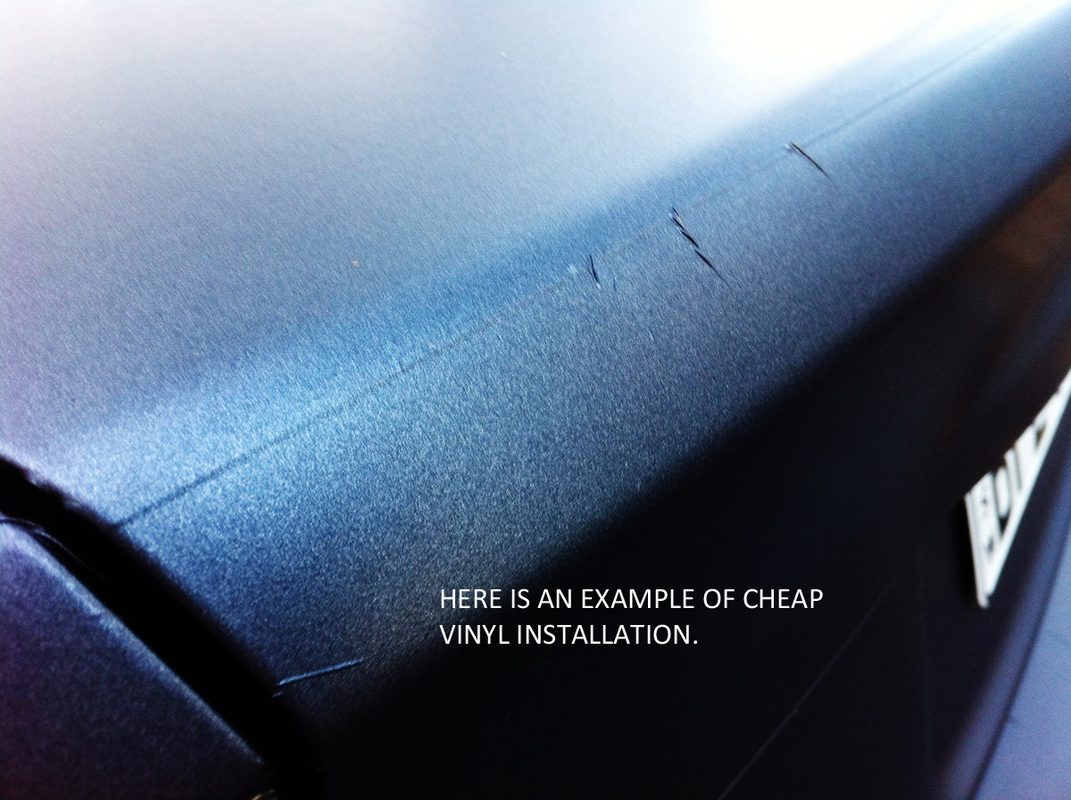

This failure on the bonnet is most likely a combination of bad quality film and bad technique. While higher quality vinyl can stretch to 30% giving you the ability to work it into shapes and dips in panels. The installer has stretched the vinyl out over the entire bonnet and then forced the vinyl down into the grooves running up the bonnet. the result of this is a huge amount of tension being placed on the film meaning over the course of the first week or so the vinyl has quite literally pulled itself back up from the tension. The rear quarter panels.

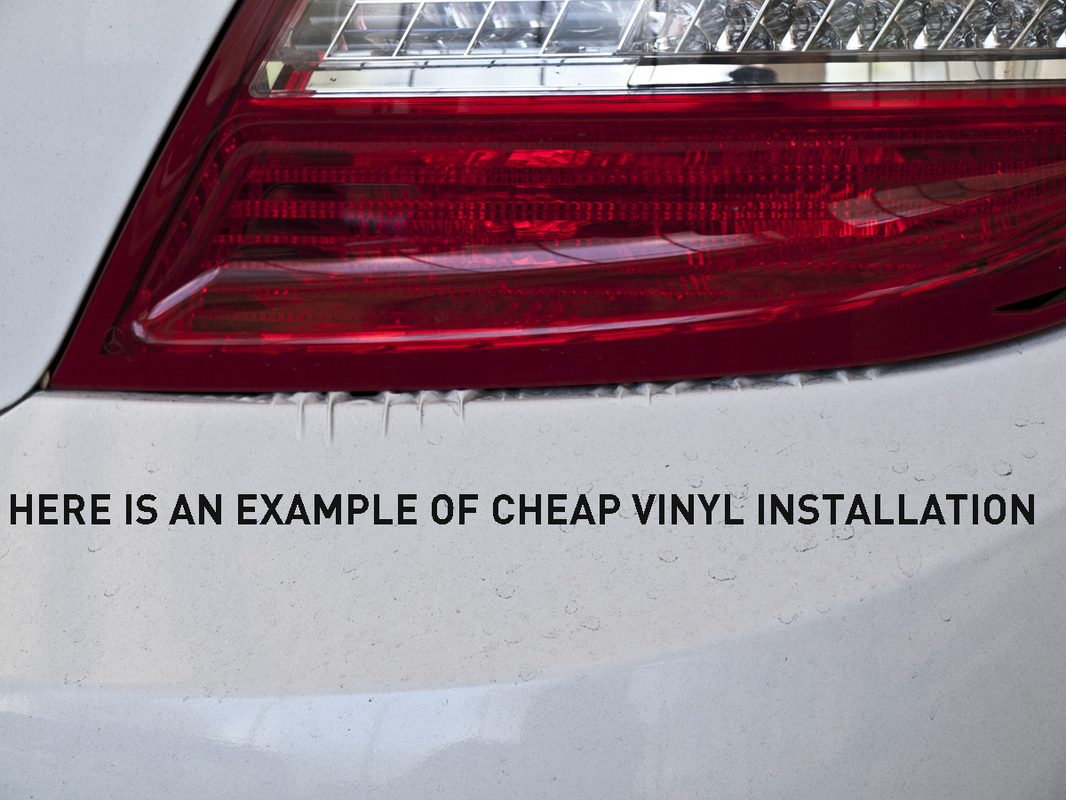

Here you can see a join and overlap running through the middle of the quarter panel from the tail light all the way to the back doors. This technique is used to avoid having to do from the dog leg panel, across the quarter panel and all the way up and over the top of the doors the the windscreen in one continuous piece. Its lazy and incorrect. The roof.

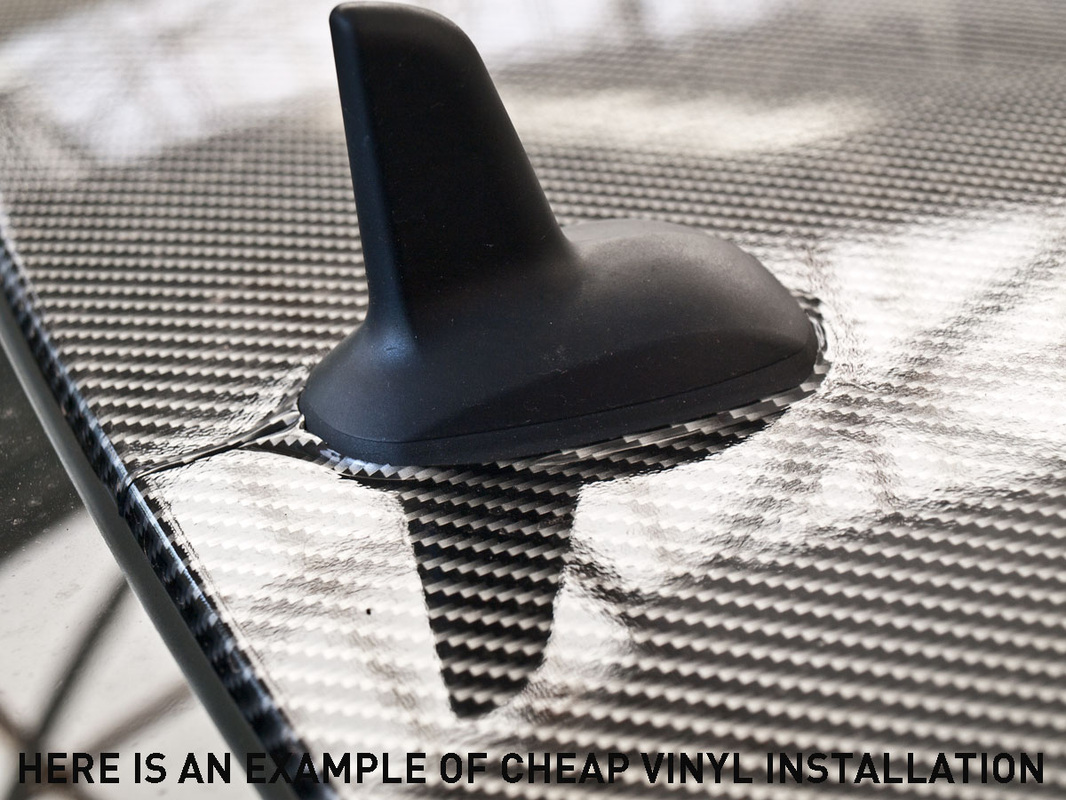

Here we see where the roof has been laid back to the aerial then sliced from the front of the aerial through the remaining vinyl. its then been pushed and forced around the aerial marring the vinyl. It has then been overlapped behind the aerial melted with a heat gun. the vinyl has then been cut around the aerial but up on the rubber, doing this leaves it prone to water entering under the vinyl and lifting as you can see at the back of the aerial. The bumpers.

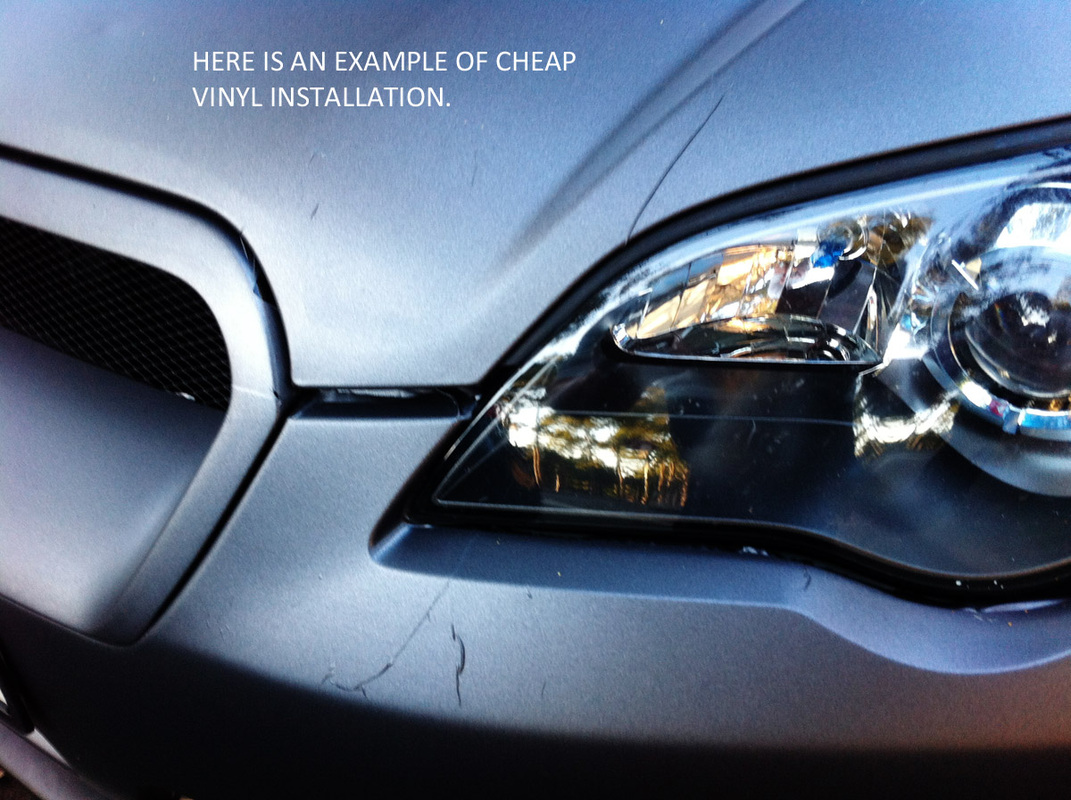

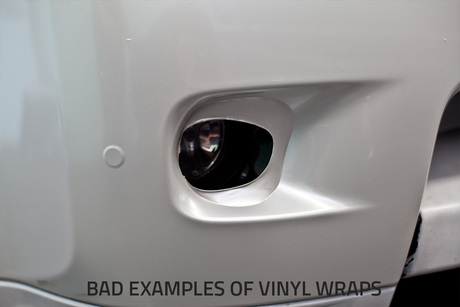

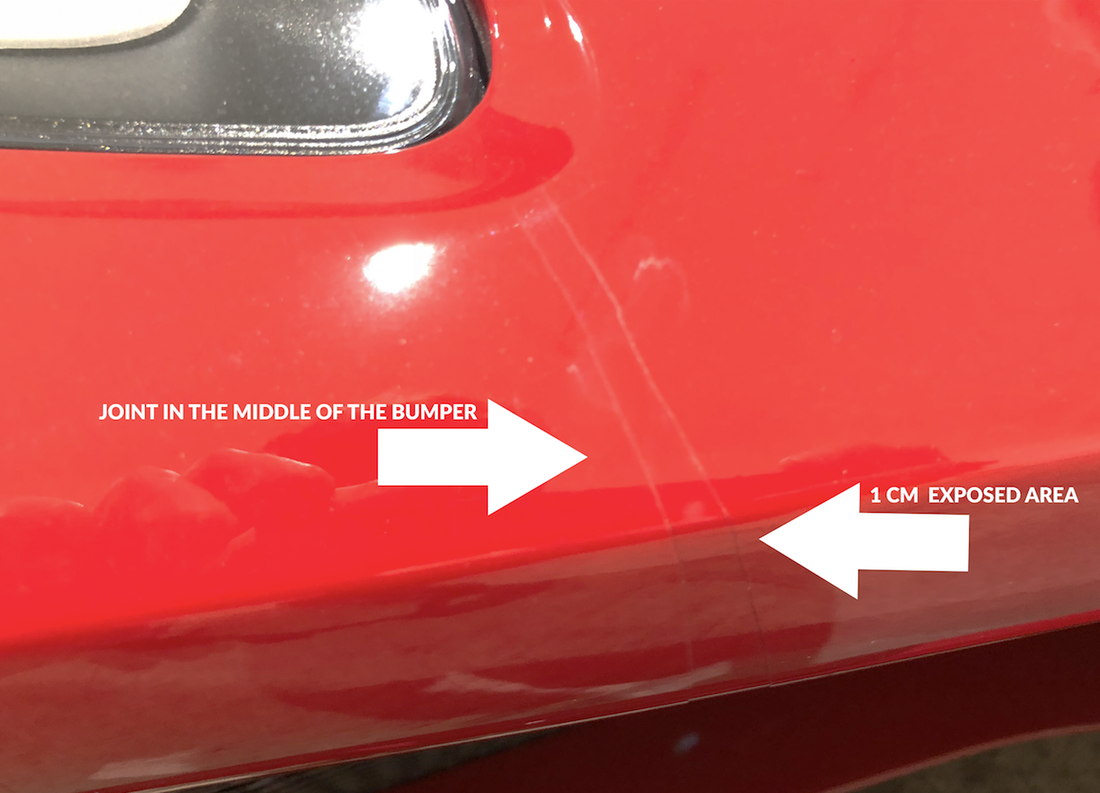

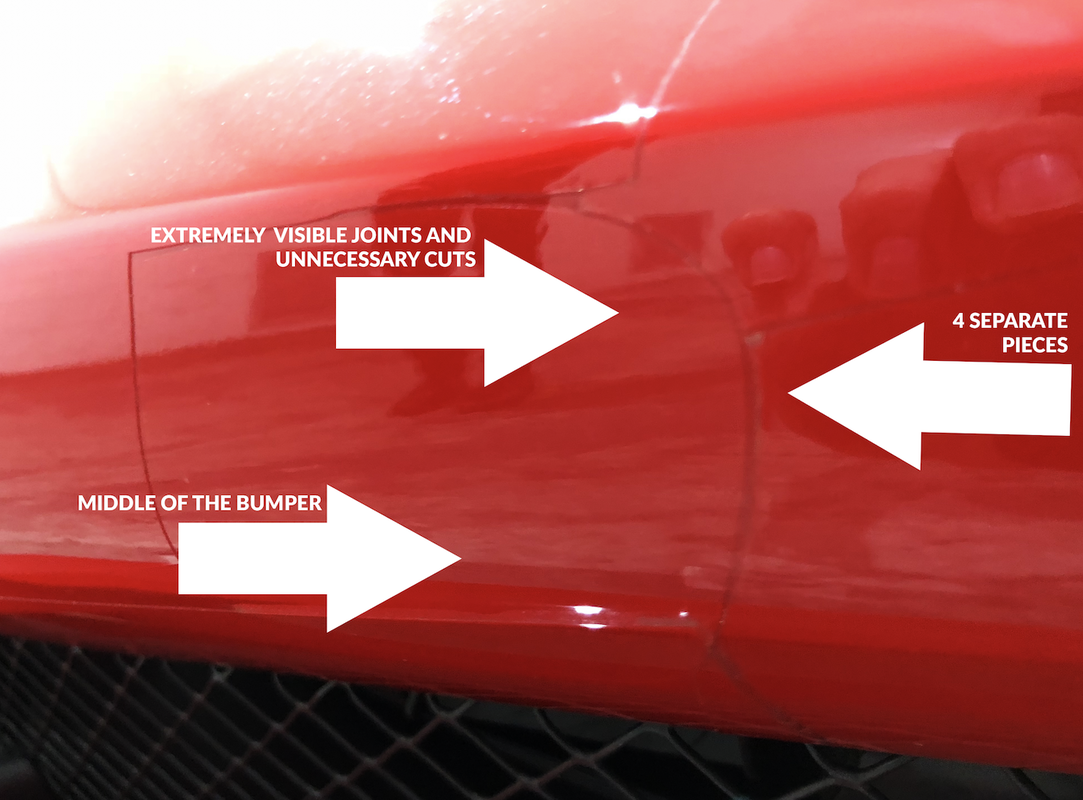

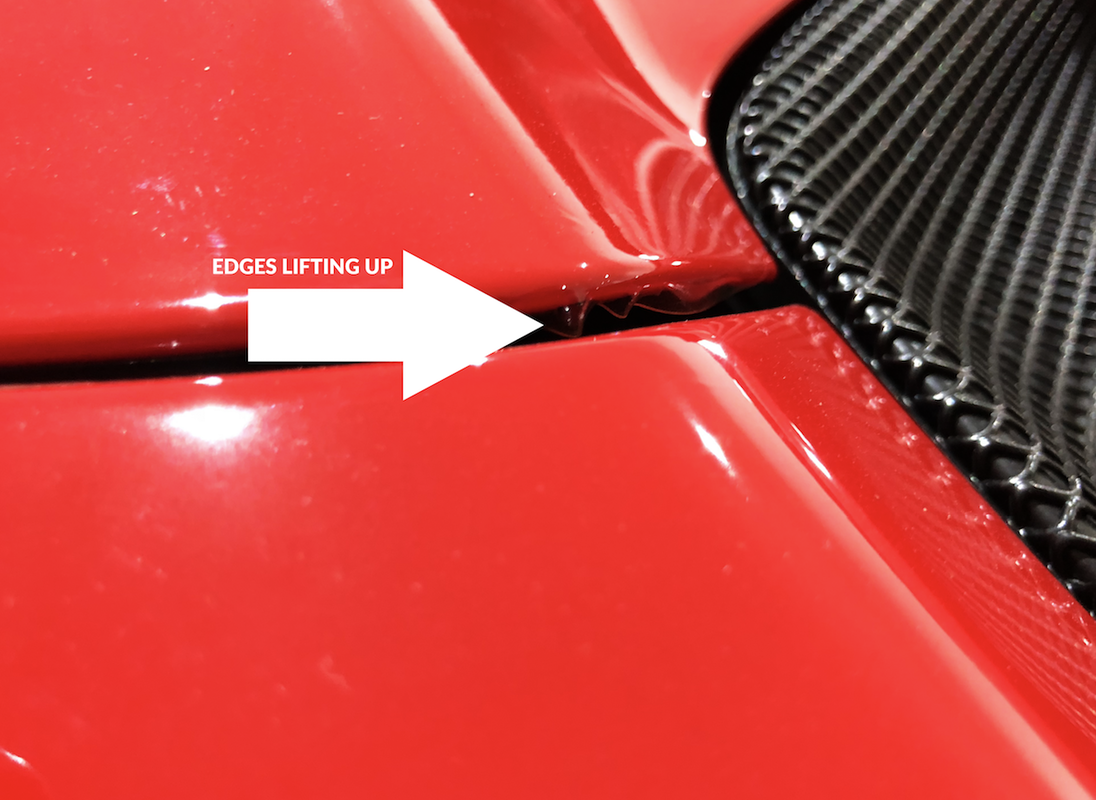

The way in which bumpers are approached is very important as being such a multi dimensional shape means during the process you can end up with alot of excess vinyl in areas or extremely high amounts of tension in areas. while tasteful and discreet infills and capping pieces are often a requirement when doing a bumper the places in which the installer chooses to put them can define weather it will be a nice finish or end up like this mercedes. As you can see around the spotlights the installer has used an infill technique, the idea behind this is to relieve excess tension by not having to force the vinyl around the spotlights, however the installer has stretched the infill and pushed it in regardless which has caused it all the spring back up. another thing to note is that joins should always be executed at a radius downwards or away from the eye. In the lower air intakes the installer has fitted infills, then during the process of cutting the holes has put the knife blade so far through that it has dragged on the infill slicing a section along the bottom, this has pulled apart later down the track exposing the silver underneath. At the headlight and taillight sections of the bumpers there are areas where excess film has been shrunk using heat trying to get rid of excess and baggy film, the issue with this is the vinyl is designed to stretch to 30% but isn't really supposed to be shrunk down. As a few weeks go by and the film starts to return to its natural size forcing it to bunch up and out as this is the only way for the material to go. Mirrors and door handles.

The bad finish on the mirrors is due to them not being dismantled before installation. it is often necessary to have stretched sections of vinyl wrapped around the back of the panel to anchor it. This will stop it pulling away from the edges. Its a similar story with the door handles. Preparation/ Fit and finish.

The biggest problem with this job aside from the shoddy installation was the way it was approached. when doing a quality vehicle wrap attention to detail is of great importance. This amg was not stripped down properly for the job. To wrap this car professionally the bars needed to be removed and the individual components of the bar needed to be removed from them. The door handles and top trims should be removed, the mirrors should be removed and dismantled, the aerial should be removed, the head and tail lights should be taken out, the boot lid and garnishes should be dismantled. the general feel of lazyness comes from this car, the installation was extremely unprofessional and the way the car was put together defied belief with bolts missing or only half fastened. The cheaper option.

There is a saying in life that says "the poor man pays twice" once to have it done and once to have it done right. The same applies to taking the cheap option. Got a cheaper quote?We get many questions about vinyl wrapping and why, if it’s a simple as the concept suggests, then why can’t they install them at home. Why should they go to a certified installer?

To answer some of these questions, the Provinyl team has written this in depth article to help explain all stages involved, from cleaning the car to the finished application. We’re also trying to inform any potential clients as to why you should choose a certified installer will benefit your car and your wallet in the long run. We use only the best material.To start off, the price of the material can vary from $10 (Chinese counterparts) to $160 (3M) per linear meter. The difference in prices here is always a major factor in the final price, and often choosing the cheaper materials with cost you more in the long term due to replacement and re-installation of vinyl. When vinyl is used on a car exterior, the high requirements of the material are to ensure that what we promise our clients is the truth.

The vinyl has to ensure protection to the paint from day to day wear, from factors such as sun damage, stone chips or accidental scratches from simple things like walking past your car. The vinyl’s we use are all up to these standards as well as holding a 5-year warrantee and being completely removable without any damage to the paintwork. When a cheap vinyl is used, over time, the colour can fade, and the glue can also become damaged. This all becomes very apparent when removing the vinyl; in worst cases paint can even be damaged or removed. We only choose the best materials to give you the piece of mind that you pride and joy will stay in pristine condition, and the vinyl you choose will hold its colour and finish for years to come. Preparation of Panel

The preparation process takes up one third of the entire job. The installer must completely clean the entire surface of the car. All surfaces need to be cleaned from all dirt, and then degrease. To ensure the vinyl does not let go of the surface, it needs to be prepared perfectly, any surface that will have vinyl applied, including the bodywork that isn't seen. For a higher quality installation, all logos and indicators are removed or covered if necessary. Any easily removable parts are taken off to have the smoothest surface possible. Once the item surface is completely free of any dust the underside edges are covered with a superimposed thin and narrow strip of primer that allows the vinyl to stay in its shape and not shrink or move under heat or time. Installing the Panel

It large factor in application is calculating in advance where and how to stretch the vinyl during application, over stretching vinyl can cause compromised contact with the surface, as the glue can become stretched. All this needs to completed quickly to ensure no dust finds it’s was back onto the surface of the car, or the vinyl. Complex surfaces like bumpers require special expertise and skillful execution. Cutting and Wrapping

Trimming is another consuming process, which requires experience from a master installer. Cutting away excess vinyl ensures the surface is completely smooth, and wrapped to the edge with no visibility of what is underneath. It is not acceptable to have any creases visible or colour showing from the original panel. One mistake at this stage, and the entire process has to be started again and re-applied. The Final Stage A post application heating of the entire surface to 90-110 Degrees Celsius along with silicone along the edges where it is most vulnerable to external factors. |

Still want it cheaper? Don't expect the highest quality. You’ve been warned by the Provinyl team.

Volvo with a fake 3M carbon fibre

|

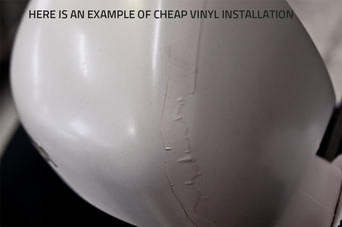

Recent customer came to PROvinyl with his brand new Volvo. His bonnet and mirrors had been wrapped and he asked us to also wrap his front bumper, roof and spoiler. He said 3M vinyl had been used but to his shock we found that it had in fact been wrapped in a cheap chinese brand of carbon fibre. The PROvinyl team removed the old vinyl with his permission and found that the cheap vinyl had left an odd pattern on the paint which was extremely difficult to remove. In addition, the workmanship was very poor and the bodywork had been scratched and damaged. We spoke to the customer and discovered that when he bought the car brand new from the Volvo dealership they arranged for one of their trusted contractors to supply and install the vinyl. He was over-charged for the work and given no warranty or guarantee. A heads up to anyone considering having their vehicle wrapped. |

Still want it cheaper? Don't expect the highest quality. You’ve been warned by the Provinyl team.

MAZDA MPSAnother heads up to all you folks considering getting any Vinyl work done. Please take a look at the pictures and be warned: This Brand new Mazda MPS had received some work elsewhere and quite frankly it was some of the worst workmanship the team has ever seen. The bonnet, side skirts, spoiler, mirrors and nose of the car had been wrapped in 3M carbon fibre vinyl to a very poor standard. The bodywork paint had been severely damaged on every panel as a result of hand cutting the vinyl against the paintwork. Not only was this clearly visible but none of the lines were straight! To add to all the poor workmanship the side skirts had been applied in several patches for no reason. Don’t trust just any one with your car - research and go and see their workmanship. Fortunately, we re-wrapped this customer’s vehicle to the PROvinyl standard. |

Range Rover in gloss pearl whiteAh the old 'my mate said his mate could do it for me'!!

Never ends well when we hear this and the range rover that showed up is a perfect example of what to expect when the cheap or convenient option is the one taken. With crazy joins and overlaps, bubbles and horrible wrapping at panel edges the only way to fix it was to peel it off and bin it. It can be removed so not such a big deal right?.........WRONG!!! With the vinyl off the truth was exposed in the form of slice marks all through the paint where the installer (if you would call them that) cut everything by hand! |

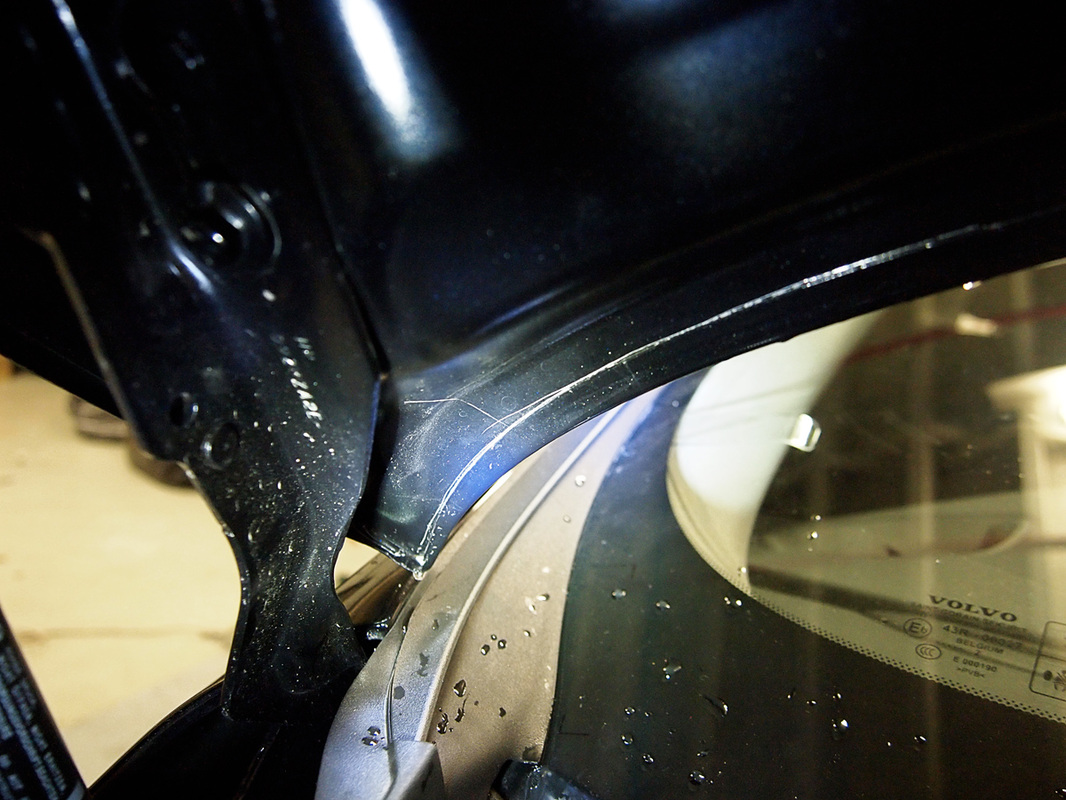

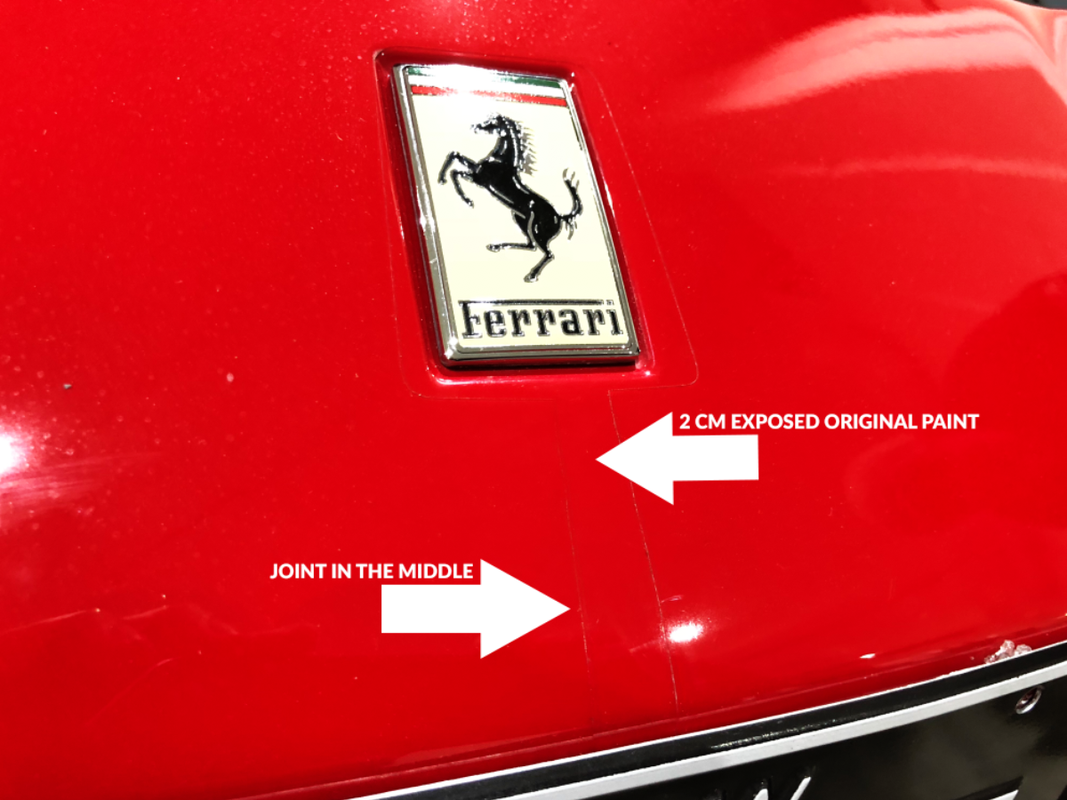

Ferrari 458 - unprofessional paint protection film installation.

Don’t let them take you for a ride! Here we see an example of a car which has had a rather bad paint protection film wrap done on it, and how you can avoid being the next victim.

This beautiful Ferrari 458 was brought to us by a customer, who had previously done a paint protection film wrap with a previous company, but was left less than impressed after the completion of this shoddy work.

This beautiful Ferrari 458 was brought to us by a customer, who had previously done a paint protection film wrap with a previous company, but was left less than impressed after the completion of this shoddy work.

While PPF is advanced in its ability to prevent paint damage to your vehicle, it’s application process remains in the hands of many people who fail to understand how to properly cover a car in the film. Keep an eye out for these examples on any car you come across with PPF, and make sure that you go to the right place for your vehicle protection. Contact us for any information you may need, or any questions you may have, and we can even help direct you to experienced professionals!